RDC

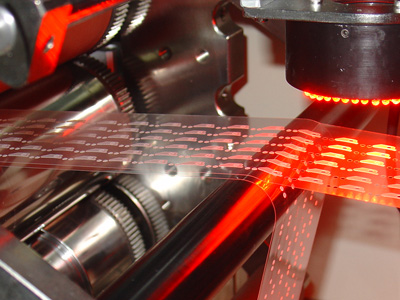

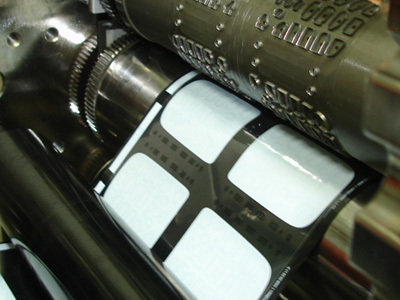

CNC Rotary Die Cutting Machine

The technology developed offers the possibility to produce multi-layers complex products in one run, with the highest accuracy available on the market, remain ahead of competition!

Home | Products | Rotary Die Cutting Serial | RDC

The technology developed offers the possibility to produce multi-layers complex products in one run, with the highest accuracy available on the market, remain ahead of competition!

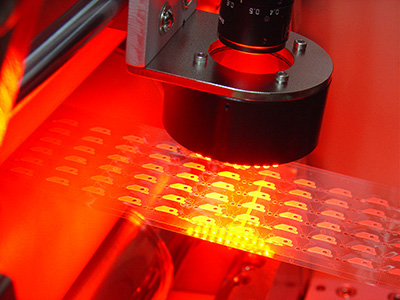

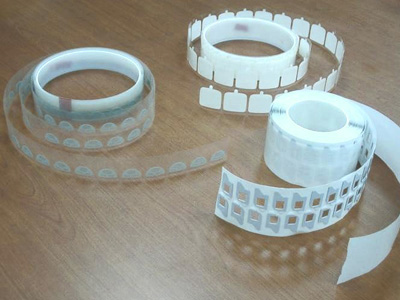

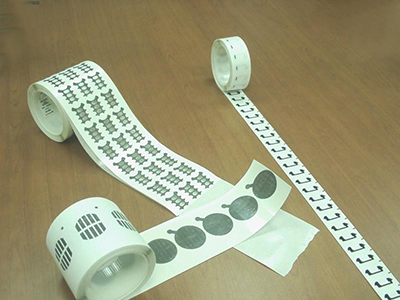

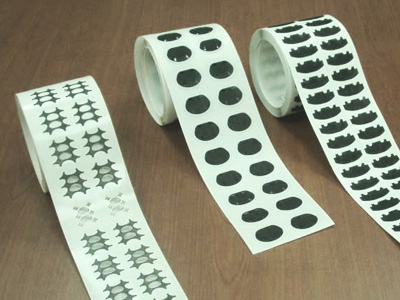

Modern manufacturing technology for converting components and multi layers products, such as components for the mobile phone, PDA, LCD, STN and smart labels, which you can do converting, laminating, CCD alignment, rotary die or laser cutting all in 1 run!

Converting, laminating, CCD alignment, rotary die cutting and laser cutting are all complete in this module.

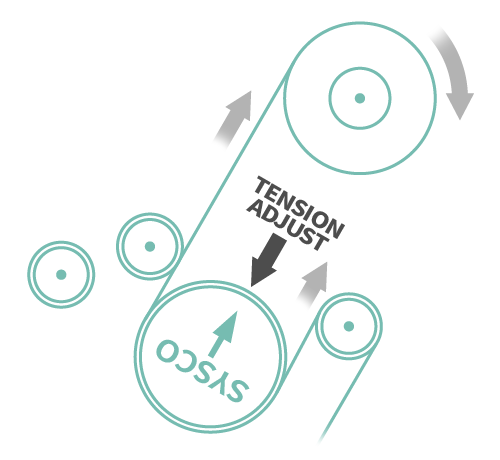

To reach high precision, the tension of each material must be very stable. Therefore, Sysco developed this tension control module with our own program to achieve high stability of material tension.

To allow more flexibility, we designed the unwind/rewind stations adjustable, depending on the properties of the product and place the stations in the most appropriate position.

The specialty of RDC system is that it provides rotary die cutting which can highly increase cutting speed. Especially combine with our self-developed control software, it not only makes accurate precision but also raise the product capacity efficiently.

| Mobile Phone / Electronics |

|

| Medical |

|

| Automobile |

|

| RFID |

|

| Labels |

|

| Solar power |

|