HCP

Manual/Automatic Plastic Card Lamination System

HCP is designed for the safe and efficient lamination of a variety of contact and contactless cards. Exceptional features to ensure perfect lamination result.

Home | Products | Card Processing Serial | HCP

HCP is designed for the safe and efficient lamination of a variety of contact and contactless cards. Exceptional features to ensure perfect lamination result.

Fully Automatic, Powerful thermal system, Large laminate area, Closed-loop transport system.

Precise pressure control, Precise temperature control, Flat laminating plan, Graviton offset device.

High rigidity structures, Famous bland component.

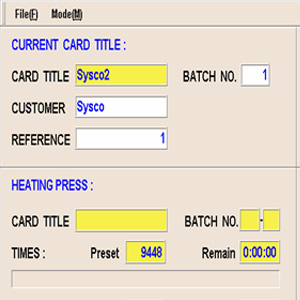

Dynamic graphic, Memory of batch production, Memory of parameter.

Energy Conservation, One man operation.

PC-based control, Fault-finding diagnostics, Programmable setting, Tilt-able lay-up station.

HCP is designed for the safe and efficient lamination of a variety of contact and contactless cards.

Card material consists of overlay films and core materials. Overlay films: PVC, ABS, Polyester. Core materials: PVC, ABS, PP, PETG, Polyester.

Suitable for lamination of contact and contactless plastic cards.